A Simple Key For precision machining Unveiled

Desktops and CNC device equipment proceed to develop swiftly. The pc revolution has a great impact on this enhancement. By the late eighties little equipment stores experienced desktop computer systems and CNC machine applications. Shortly immediately after, hobbyists, artists, and designers commenced obtaining CNC mills and lathes.

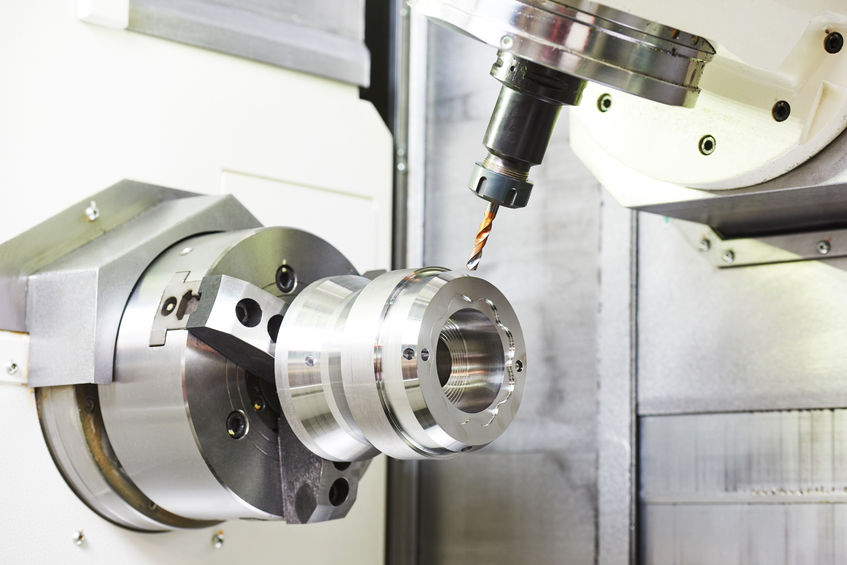

This relative movement is achieved in most machining Procedure by the use of a Key movement, referred to as "slicing speed" as well as a secondary movement termed "feed".[7] The shape with the Resource and its penetration in to the perform surface area, combined with these motions, deliver the desired condition with the ensuing get the job done area. Machining operations[edit]

industrial procedures of metalworking by chip elimination; executed by cutters on metalcutting device equipment to impart the demanded condition, dimensions, and surface end to steel areas.

Detailed Notes on machining

Milling operations are functions by which the reducing Software rotates to carry slicing edges to bear in opposition to the workpiece. Milling equipment will be the principal device Instrument Employed in milling.

) The most successful milling device style and design to emerge throughout this period was the Lincoln miller, which in lieu of getting a specific make and product of equipment Software is actually a family of equipment crafted by many corporations on a typical configuration over several many years. It took its title from the very first organization to put one that you can buy, George S. Lincoln & Corporation (formerly the Phoenix Iron Is effective), whose first a person was built in 1855 for that Colt armory.[twenty five]

The whole process of photochemical machining takes advantage of a photosensitive polymer named photoresist to produce a mask that is very precise and selectively guards the sheet from acid. Our engineers develop a Instrument that contains a unfavorable graphic of the part action and recurring throughout. This Device is applied to show that impression onto the photoresist.

Machining almost always is really a course of action wherever a reducing Software removes material to result the specified modify during the workpiece. Generally, driven machinery is needed to function the cutting resources. See Production approaches

It seems like you may be having issues enjoying this video clip. In that case, make sure you try out restarting your browser.

5 Simple Techniques For machining

quality approach creation backorder technique mounted Price tag marginal Expense

Precisely what is precision grip? A precision grip is the best way you seize an object involving the opposedtactile pads of the information from the thumb along with the fingers. Tactile padsare areas of the pores and skin which might be Particularly delicate to stress.

Reaming has become the sizing operations that eliminates a small level of metal from the hole by now drilled.

The chopping depth will be the thickness (in mm) of your layer of steel taken off for each pass (the space amongst the function surface area and the machined floor, calculated alongside the traditional). The reducing things (Bodily parameters) viewed as in the cross area of the layer of metal that is definitely taken out (see Figure one) are classified as the thickness and width with the layer staying eradicated; their magnitude at constants t and s depends upon the aspect cutting-edge angle ø

Fascination About machining

The choice amongst vertical and horizontal spindle orientation in usinagem milling equipment layout commonly hinges on the shape and dimension of a workpiece and the quantity of sides of your workpiece that need machining. Get the job done in which the spindle's axial movement is usual to at least one aircraft, by having an endmill as being the cutter, lends itself to some vertical mill, wherever the operator can stand before the equipment and possess easy accessibility into the slicing action by seeking down upon it.